Worm Gearbox for Waste Sorting Conveyor Adjustments

Understanding Worm Gearbox

The worm gearbox, also known as a worm drive, is a type of gear system typically used to drastically reduce speed or increase torque. They are an integral part of many industrial and mechanical applications due to their unique property of being able to provide high torque output with a compact size. This makes them a versatile and efficient solution for a variety of machinery and systems.

Working Principle of Worm Gear Reducer

The worm gear reducer operates based on the meshing relationship between the worm and the worm wheel. The worm, which is a screw-like device, meshes with the teeth on the peripheral surface of the worm wheel. This interaction enables the transmission of motion and power in a smooth and efficient manner. The rotation of the worm causes the worm wheel to rotate, thereby enabling the gearbox to reduce speed or increase torque as required.

Basic Structure of Worm Gearbox

The worm gearbox is composed of several essential components, including the worm, worm wheel, input shaft, and output shaft. These parts function together to enable the gearbox to perform its intended task. The worm is connected to the input shaft, and it meshes with the worm wheel, which is connected to the output shaft. The input shaft receives power from the power source, and the output shaft delivers the output power to the load.

Why Worm Gearbox is Suited for Waste Sorting Conveyor Adjustments

- High Torque: Worm gearboxes provide high torque output, making them ideal for applications like waste sorting conveyors that require significant power to move heavy loads.

- Compact Size: Despite their high torque output, worm gearboxes are compact in size, making them suitable for installations where space is a constraint.

- Smooth Operation: The meshing relationship between the worm and the worm wheel ensures smooth and quiet operation, which is essential in a waste sorting environment.

- Durability: Worm gearboxes are known for their durability and long service life, reducing the need for frequent maintenance or replacement.

- Efficient Power Transmission: Worm gearboxes are efficient in transmitting power, making them an ideal choice for waste sorting conveyor systems.

Features and Advantages of Worm Gear Motor

- High Efficiency: Worm gear motors are known for their high efficiency in power transmission, making them a popular choice in various industrial applications.

- Long Service Life: These motors are designed for durability and can withstand harsh operating conditions, ensuring a long service life.

- Low Noise: Worm gear motors operate quietly, making them suitable for environments where noise reduction is necessary.

- High Torque Output: These motors are capable of delivering high torque output, making them ideal for heavy-duty applications like waste sorting conveyors.

Choosing the Right Worm Reducer for Your Application

Several factors should be considered when choosing a worm reducer for your application. These include the required torque output, the space available for installation, the operating environment, and the expected service life. It’s also important to consider the reducer’s efficiency, noise level, and maintenance requirements.

Motors for Worm Gear Reducers

Worm gear reducers and motors go hand in hand in delivering the desired output. A motor provides the necessary power for the reducer to efficiently reduce speed or increase torque. We also offer a range of electric motors that are compatible with our worm gear reducers.

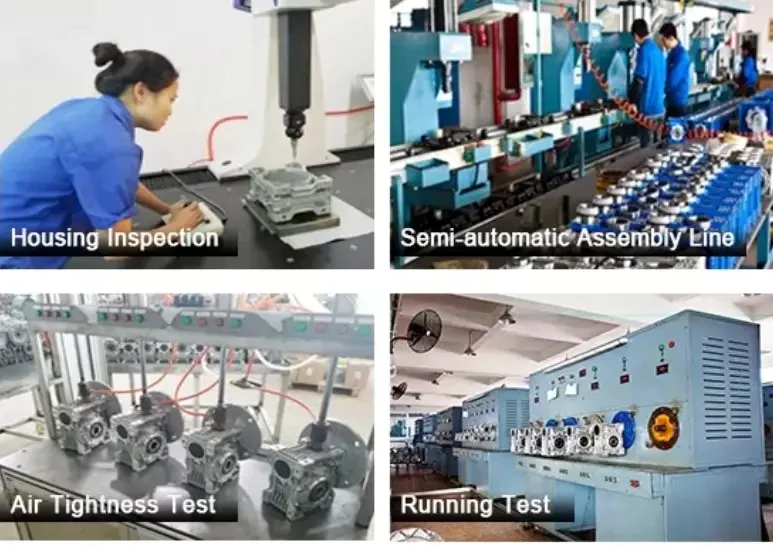

About Our Company

We are a comprehensive transmission equipment manufacturer integrating research and development, manufacturing, and sales of speed reducers. With more than 15 years of experience in the field, we have served customers across Europe, America, Africa, Asia, and have garnered much praise from the market. We are committed to providing superior service, high-quality products, and competitive pricing. Our product range includes MRV series worm gear reducer, GV series gear reducer, RT series solar reducer, XV series planetary reducer, BD series harmonic reducer, and various types of non-standard reducer, all of which are widely used across industries. We invite you to explore our products and contact us for your requirements.

Common Questions and Answers

- Q: What is the service life of your worm gearbox?

A: Our worm gearboxes are designed for durability and can last for many years with proper maintenance. - Q: Can your worm gearboxes withstand harsh operating conditions?

A: Yes, our worm gearboxes are built to withstand harsh environments and are suitable for a variety of industrial applications. - Q: Do you provide custom solutions for specific applications?

A: Yes, we can provide custom solutions based on your unique requirements. Please contact us for more information.

Edited by Zqq.