Worm Gearbox for Thermal Vent Adjustment in Greenhouses

As a significant contributor in the mechanism industry, Worm Gearbox plays an integral role in various applications, including thermal vent adjustments in greenhouses. This article will explore the concept, structure, and importance of Worm Gearbox in the industrial and mechanical sector.

Understanding the Basics of Worm Gearbox

The Worm Gearbox or Worm Drive is a specific gear composition in which a worm (which is a gear in the form of a screw) meshes with a worm gear (which is similar in appearance to a spur gear). The system is designed to reduce rotational speed or allow higher torque to be transmitted.

The Significance of Worm Gearbox in Industrial and Mechanical Applications

Worm Gearboxes are predominantly used in heavy-duty applications because they can manage high shock loads with fewer vibrations. They are compact and provide high torque output. They also offer smooth and silent operation, making them suitable for use in noise-sensitive environments.

The Working Principle of Worm Gearbox in Thermal Vent Adjustment

The operation of a worm gearbox revolves around the intimate connection between the worm and the worm gear. The worm, which is similar to a standard spur gear, is in a screw shape. The worm gear, on the other hand, is a helical gear having a specific groove for the worm to correctly fit in. The worm’s rotation enables the worm gear to move, which is precisely how the motion is transmitted.

Structural Composition of Worm Gearbox

The primary components of a worm gearbox include the worm, worm gear, input shaft, and output shaft. These components are interconnected in a manner that allows for efficient transmission of motion.

Worm

The worm is the primary driving component of the gearbox. It is a screw-shaped gear that rotates to transmit motion to the worm gear.

Worm Gear

The worm gear is a helical gear that receives motion from the worm. It’s designed to fit perfectly with the worm for efficient motion transmission.

Input Shaft and Output Shaft

The input shaft is connected to the power source, and it’s the component that initiates the motion in the gearbox. The output shaft, on the other hand, is the component that carries the motion from the gearbox to the machinery.

Why Worm Gearbox is Suitable for Thermal Vent Adjustment in Greenhouses

There are several reasons why the Worm Gearbox is an ideal choice for controlling thermal vents in greenhouses.

- High Torque Output: Worm Gearboxes are capable of producing high torque outputs which are necessary for the smooth operation of thermal vents.

- Compactness: Given their compact and robust design, Worm Gearboxes are easy to install in confined spaces in greenhouses.

- Efficiency: They operate efficiently under heavy-duty operations without any significant wear and tear.

- Smooth Operation: Worm Gearboxes offer smooth and noiseless operation, making them ideal for environments like greenhouses.

- Low Maintenance: Given their robust construction, these gearboxes require minimal maintenance.

Characteristics and Advantages of Worm Gear Motor

There are numerous benefits of using a Worm Gear Motor. Here are some of the most notable ones:

- High Efficiency: Worm Gear Motors are known for their high efficiency and low energy consumption.

- High Load Carrying Capacity: These motors can handle heavy loads with ease.

- Extended Lifespan: The robust construction of Worm Gear Motors ensures a longer lifespan.

- Low Noise: These motors operate quietly, which is ideal for noise-sensitive environments like greenhouses.

- Easy Maintenance: Worm Gear Motors require minimal maintenance, reducing the overall operation cost.

Choosing the Right Worm Reducer for Your Application

When choosing a worm reducer for your application, there are several factors that you need to consider.

- Load Requirements: The worm reducer you choose should be able to handle the load requirements of your application.

- Speed Requirements: Consider the speed requirements of your application. Different worm reducers offer different speed ratios.

- Size and Installation: Make sure the worm reducer fits well in your application and is easy to install.

- Cost: Consider your budget and the cost of the worm reducer. While it may be tempting to go for the cheapest option, it’s often better to invest in a high-quality product that will last longer and deliver better performance.

Motors for Worm Gear Reducers

The Worm Gear Reducer and the motor are inseparable. The motor provides the initial power that the reducer uses to reduce the speed and increase the torque. We also provide compatible electric motors for our Worm Gear Reducers.

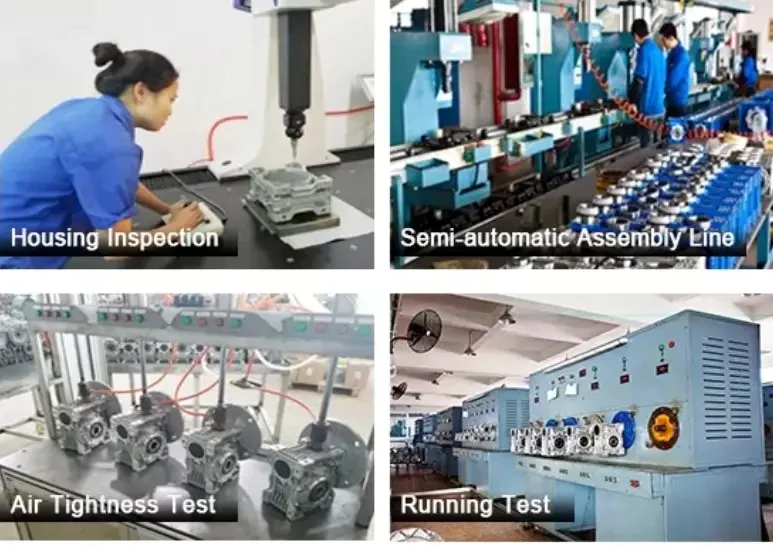

About Our Company

We are a comprehensive transmission equipment manufacturer with more than 15 years of experience in the design, production, manufacture, and sales of gearboxes. Our consistent mission and vision, our company has introduced advanced production equipment and testing equipment at home and abroad. We have served customers in Europe, America, Africa, Asia, and have won the market’s praise.

Q&A

- Q: What is the lifespan of your Worm Gearbox?

A: The lifespan of our Worm Gearbox depends on the application and maintenance. However, with regular maintenance, it can last for several years. - Q: Can your Worm Gearbox handle heavy-duty applications?

A: Yes, our Worm Gearboxes are designed to handle heavy-duty applications efficiently. - Q: Do you provide after-sales service?

A: Yes, we provide excellent after-sales service to ensure customer satisfaction.

Edited by Zqq