Worm Gearbox for Microbrewery Stirring Systems: The Ultimate Guide

Understanding the Basics of Worm Gearbox

A worm gearbox, also known as worm drive, is a type of gear system that consists of a worm (a screw-like gear) and a worm gear (similar to a spur gear), where the worm gear is driven by the worm. It is a fundamental part of numerous industrial and mechanical applications due to its robustness and efficiency in reducing speed and increasing torque.

The Importance in Industrial and Mechanical Applications

Worm gearboxes play a crucial role in various industries due to their unique features, such as self-locking ability, compact structure, low noise, and high transmission ratio. This makes them particularly suitable for applications where space is tight, and noise and vibration need to be minimized.

Working Principle of Worm Gear Reducer

At the heart of a worm gear reducer, a worm (worm shaft) and a worm gear engage to create a compact and efficient drive system. The worm shaft rotates against the worm gear, which is held in a fixed position, causing the worm gear to rotate around its own axis. This rotary motion is then transferred to the output shaft of the gearbox. The unique engagement between the worm and worm gear allows the transmission of high torque and reduces the speed of the output shaft in comparison with the input shaft.

Basic Structure and Components of a Worm Gearbox

Worm and Worm Gear

The worm, similar to a screw, meshes with the worm gear to transmit motion and power. The worm gear, which resembles a standard spur gear, works in tandem with the worm to reduce rotational speed or transmit higher torque.

Input and Output Shafts

The input shaft is connected to the power source and brings in the rotary motion. The output shaft is connected to the load and delivers the reduced speed or increased torque from the gearbox.

Why Worm Gearbox is Suitable for Microbrewery Stirring Systems

Worm gearboxes are an excellent choice for microbrewery stirring systems due to several reasons:

- They offer high torque for effective stirring.

- They provide a high reduction ratio in a compact size.

- They operate quietly and smoothly, which is crucial in a microbrewery environment.

- They require less maintenance and are durable, which reduces downtime and increases productivity.

- They have a self-locking feature that prevents the system from back-driving, ensuring safety.

Characteristics and Advantages of Worm Gear Motor

Worm gear motors offer a host of benefits that make them ideal for microbrewery stirring systems:

- High Torque: Worm gear motors provide high torque output, making them perfect for stirring applications that require a strong force.

- Compact Size: Despite their high torque output, worm gear motors are compact, making them an excellent choice for applications where space is limited.

- Quiet Operation: Worm gear motors operate quietly, making them suitable for environments where noise levels need to be minimized.

- High Durability: These motors are built to last, ensuring a long service life and fewer maintenance requirements.

- High Efficiency: Worm gear motors are highly efficient, ensuring optimal performance with minimal energy consumption.

Selecting the Right Worm Reducer for Your Microbrewery Stirring System

Choosing the right worm reducer requires considering several factors:

- Torque Requirements: The worm reducer should be able to provide the necessary torque for your stirring system.

- Speed Requirements: It should also meet the speed requirements of your system.

- Size Limitations: The worm reducer should fit in the available space in your system.

- Cost: It should be within your budget.

- Quality and Durability: The worm reducer should be of high quality and durable to ensure a long service life and fewer maintenance requirements.

Motors for Worm Gear Reducers

Worm gear reducers work hand in hand with electric motors to create a complete and efficient drive system. The motor provides the power that the reducer needs to reduce speed and increase torque. Our company also offers electric motors that are perfectly compatible with our worm gear reducers.

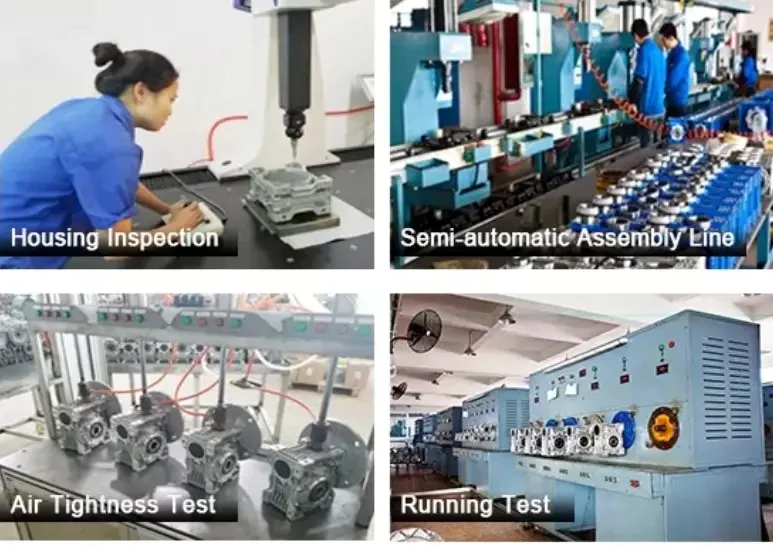

About Us: Your Trusted Provider of Worm Gearboxes

We are a comprehensive transmission equipment manufacturer integrating research, development, manufacturing, and sales of speed reducers. Our product range includes the MRV series worm gear reducer, GV series gear reducer, RT series solar reducer, XV series planetary reducer, BD series harmonic reducer, and various types of non-standard reducer. With over 15 years of experience, we have served customers worldwide, and our products are widely used in different industries. We are committed to providing high-quality products, excellent service, and competitive prices.

FAQs

1. What is a worm gearbox?

A worm gearbox is a type of gear system that consists of a worm and a worm gear. It is used to reduce speed and increase torque.

2. Why is a worm gearbox suitable for microbrewery stirring systems?

Worm gearboxes are suitable for microbrewery stirring systems due to their high torque output, compact size, quiet operation, high durability, and high efficiency.

3. How do I choose the right worm reducer for my system?

You should consider factors such as torque requirements, speed requirements, size limitations, cost, and the quality and durability of the worm reducer.

Edited by Zqq.