Worm Gearbox for Olympic Timing Gate Adjustments

Introduction to Worm Gearbox

The worm gearbox, also known as the worm drive, is a type of gear system typically used in various mechanical and industrial applications. They are renowned for their ability to provide high torque output with a compact design, making them ideal for many applications, including the precise adjustments needed for Olympic Timing Gates.

The Importance of Worm Gearbox in Industrial and Mechanical Applications

Worm gearboxes are crucial in many industrial and mechanical applications. These include conveyor systems, material handling equipment, and lifts and elevators, to name a few. Their unique design allows for large gear reductions, making them an excellent choice for applications requiring slow speed and high torque.

Working Principle of Worm Gear Reducer

The worm gear reducer works on a simple principle: the worm (a gear in the form of a screw) meshes with the worm gear, transferring rotation into linear motion. This interaction presents a unique mechanical advantage, as the worm can easily turn the gear, but the gear cannot turn the worm, creating a locking mechanism.

Basic Structure and Components of Worm Gearbox

Worm Gears

The worm gear is the large, disc-shaped gear in the gearbox. It is usually made of bronze or a similar material.

Worm

The worm is the small, screw-shaped gear that meshes with the worm gear. It is typically made of hardened steel.

Input Shaft

The input shaft is connected to the power source and turns the worm.

Output Shaft

The output shaft is connected to the worm gear and provides the output motion.

Why Worm Gearbox is Suitable for Olympic Timing Gate Adjustments?

There are several reasons why a worm gearbox is perfectly suited for adjusting Olympic Timing Gates:

- High Torque: Worm gearboxes provide high torque output, which is necessary for moving the gates.

- Precision: The nature of the worm gearbox allows for precise movements, essential for accurate timing.

- Reliability: Worm gearboxes are known for their reliability, ensuring consistent performance.

- Simplicity: They are relatively simple machines, meaning maintenance and repair are straightforward.

- Locking Mechanism: The inherent locking mechanism prevents the gates from moving unintentionally.

Characteristics and Advantages of Worm Gear Motor

Worm gear motors come with a plethora of benefits:

- Compact Design: Their design allows for high torque output in a small package.

- High Efficiency: They are incredibly efficient, especially in high-ratio applications.

- Quiet Operation: Worm gear motors operate quietly, making them ideal for noise-sensitive environments.

- Excellent Durability: These motors are designed to last and can withstand tough working conditions.

- Wide Range of Ratios: Worm gearboxes offer a wide range of gear ratios, allowing for a variety of speeds and torques.

How to Choose the Right Worm Reducer?

Choosing the right worm reducer is crucial for ensuring optimal performance. Here are some factors to consider:

- Torque Requirements: Ensure the gearbox can handle the required torque.

- Speed Requirements: Consider the necessary speed and choose a gearbox with a suitable gear ratio.

- Size Constraints: The gearbox should fit within the available space.

- Operational Environment: Choose a gearbox that can withstand the operating conditions.

- Maintenance Requirements: Consider the maintenance requirements and choose a gearbox that can be easily serviced.

Motors for Worm Gear Reducers

Just as the worm gearbox plays a crucial role in applications like Olympic Timing Gate adjustments, so does the motor that drives it. Our company also offers electric motors that perfectly complement our worm gearboxes.

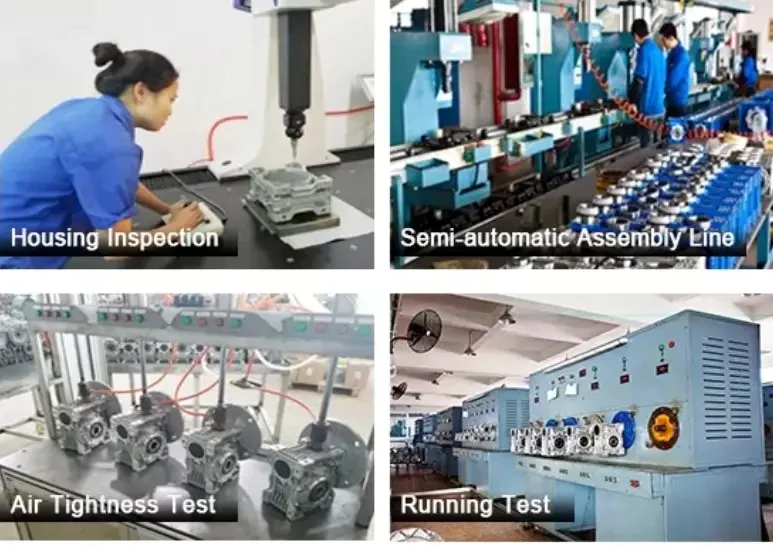

The Excellence of Our Worm Gearboxes

As a leading manufacturer with more than 15 years of industry experience, we provide top-quality worm gearboxes that are widely used across various industries. Our gearboxes are trusted and praised by customers in Europe, America, Africa, and Asia, thanks to our commitment to quality, service, and competitive pricing.

Frequently Asked Questions

What is the lifespan of a worm gearbox?

With proper maintenance, a worm gearbox can last for many years, even under heavy use.

What maintenance is required for a worm gearbox?

Regular lubrication and inspection of the gears for wear and damage can help extend the life of the worm gearbox.

Can I customize my worm gearbox?

Yes, we provide customization services to meet specific requirements and applications.

Edited by Zqq.