Worm Gearbox for Quantum Experiment Alignment Devices

Worm gearboxes play a significant role in a myriad of applications, especially in Quantum Experiment Alignment Devices. This blog post aims to shed light on the concept, operation, structure, and suitability of worm gearboxes in these devices. Let’s delve into the complexities and intricacies of this integral mechanical component.

Understanding the Basics: What is a Worm Gearbox?

A worm gearbox, also known as a worm drive, is a type of gear system that consists of a worm (resembling a screw) and a worm gear (similar to a typical mechanical gear). The arrangement allows for a high torque output, a compact design, and a right-angle configuration between input and output shafts. It is particularly useful in applications where space is limited and a high gear ratio is required.

The Significance of Worm Gearboxes in Industrial and Mechanical Applications

Worm gearboxes are essential in various industrial and mechanical applications due to their unique design and operation principles. They offer high torque output, compactness, and a high gear reduction ratio, making them ideal for heavy-duty operations. Moreover, the self-locking feature of worm gearboxes prevents the system from back-driving, ensuring safety and reliability in applications such as lifts and conveyor systems.

How Does a Worm Gear Reducer Work?

In a worm gearbox, the worm (which is on the input shaft) meshes with the worm gear on the output shaft. The worm’s threads engage with the gear’s teeth, causing the worm gear to rotate. This rotation is transmitted to the output shaft, providing the desired speed reduction or torque amplification. The high gear reduction ratio is achieved due to the large number of teeth on the worm gear compared to the single or double-threaded worm.

Worm Gearbox: Basic Structure and Components

A worm gearbox comprises several key components, each playing a crucial role in its operation. These include:

- Worm: This is the primary input component, which looks like a screw. It meshes with the worm gear to transmit motion.

- Worm Gear: The worm gear engages with the worm to convert and amplify the input rotation into a higher torque output.

- Input Shaft: The input shaft houses the worm and is connected to the power source.

- Output Shaft: The output shaft is connected to the worm gear and delivers the final output of the gear system.

Why is a Worm Gearbox Suitable for Quantum Experiment Alignment Devices?

Worm gearboxes are particularly suited for Quantum Experiment Alignment Devices due to several reasons:

- High Precision: Worm gearboxes provide high precision, which is crucial for alignment devices used in quantum experiments.

- Compact Design: Their compact design allows for easy integration into quantum experiment setups.

- High Torque: They offer high torque output, necessary for moving and aligning heavy components in these devices.

- Self-locking Feature: The self-locking feature ensures the alignment remains stable even when power is not applied.

- Right-angle Configuration: The right-angle configuration between the input and output shafts is ideal for limited space environments typical in quantum experiment setups.

Characteristics and Advantages of Worm Gear Motors

Worm gear motors offer several distinct advantages, including:

- High Torque Output: They can deliver high torque output, which is beneficial for applications requiring significant force.

- Compact Design: Their compact design makes them suitable for quantum experiment alignment devices.

- High Gear Reduction Ratios: They offer high gear reduction ratios, enabling precise control of output speed and torque.

- Quiet Operation: They operate quietly, which is crucial in environments where noise can interfere with sensitive measurements.

- Self-locking Capability: Their self-locking capability ensures safety and reliability in various applications.

Choosing the Right Worm Reducer for Your Application

When selecting a worm reducer for quantum experiment alignment devices, several factors need to be considered:

- Torque Requirements: The worm reducer must be able to deliver the required torque for the specific application.

- Size Constraints: The worm reducer’s size should fit within the space constraints of the device.

- Operating Environment: The worm reducer should be able to operate effectively in the device’s environmental conditions.

- Cost: The worm reducer should be cost-effective, providing the best value for money.

- Manufacturer’s Reputation: The manufacturer’s reputation for quality and reliability should be taken into account.

Motors for Worm Gear Reducers

The motor is an essential component of any worm gear reducer as it provides the input power for the system. Choosing the right motor that can efficiently and effectively drive the worm gearbox is crucial. We also offer electric motors specifically designed to work in tandem with our worm gearboxes for optimal performance.

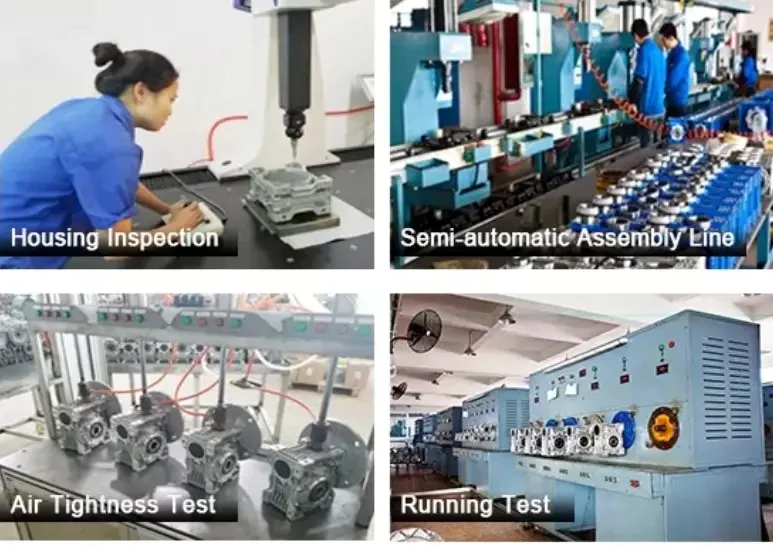

A Showcase of Our Worm Gearboxes

We are proud to be a leading manufacturer of high-quality worm gearboxes. With over 15 years of experience, we have earned a reputation for excellence in the design, production, and sales of gearboxes. We serve customers across Europe, America, Africa, and Asia, and have received consistent praise for our exceptional service, top-tier product quality, and competitive pricing. We welcome you to explore our offerings and contact us for any inquiries or purchases.

FAQs

1. What makes worm gearboxes suitable for Quantum Experiment Alignment Devices?

Worm gearboxes offer high precision, compact design, high torque output, self-locking feature, and right-angle configuration, all of which are beneficial for Quantum Experiment Alignment Devices.

2. How does a worm gearbox work?

A worm gearbox works by having a worm on the input shaft mesh with a worm gear on the output shaft. This arrangement provides a high gear reduction ratio and high torque output.

3. What factors should be considered when selecting a worm reducer?

When selecting a worm reducer, consider factors such as torque requirements, size constraints, operating environment, cost, and the manufacturer’s reputation.

Edited by Zqq.